SLIDING DOOR BLANKS

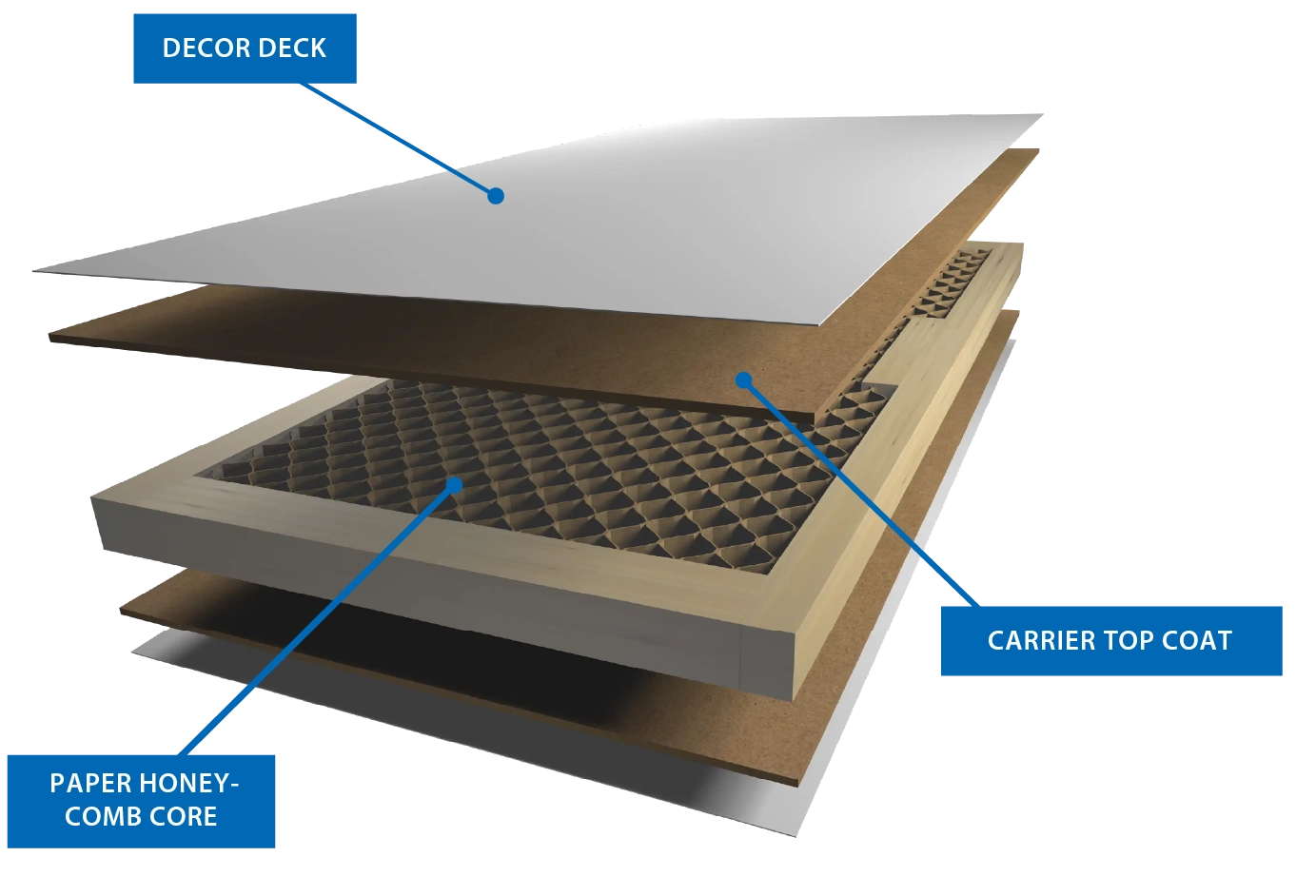

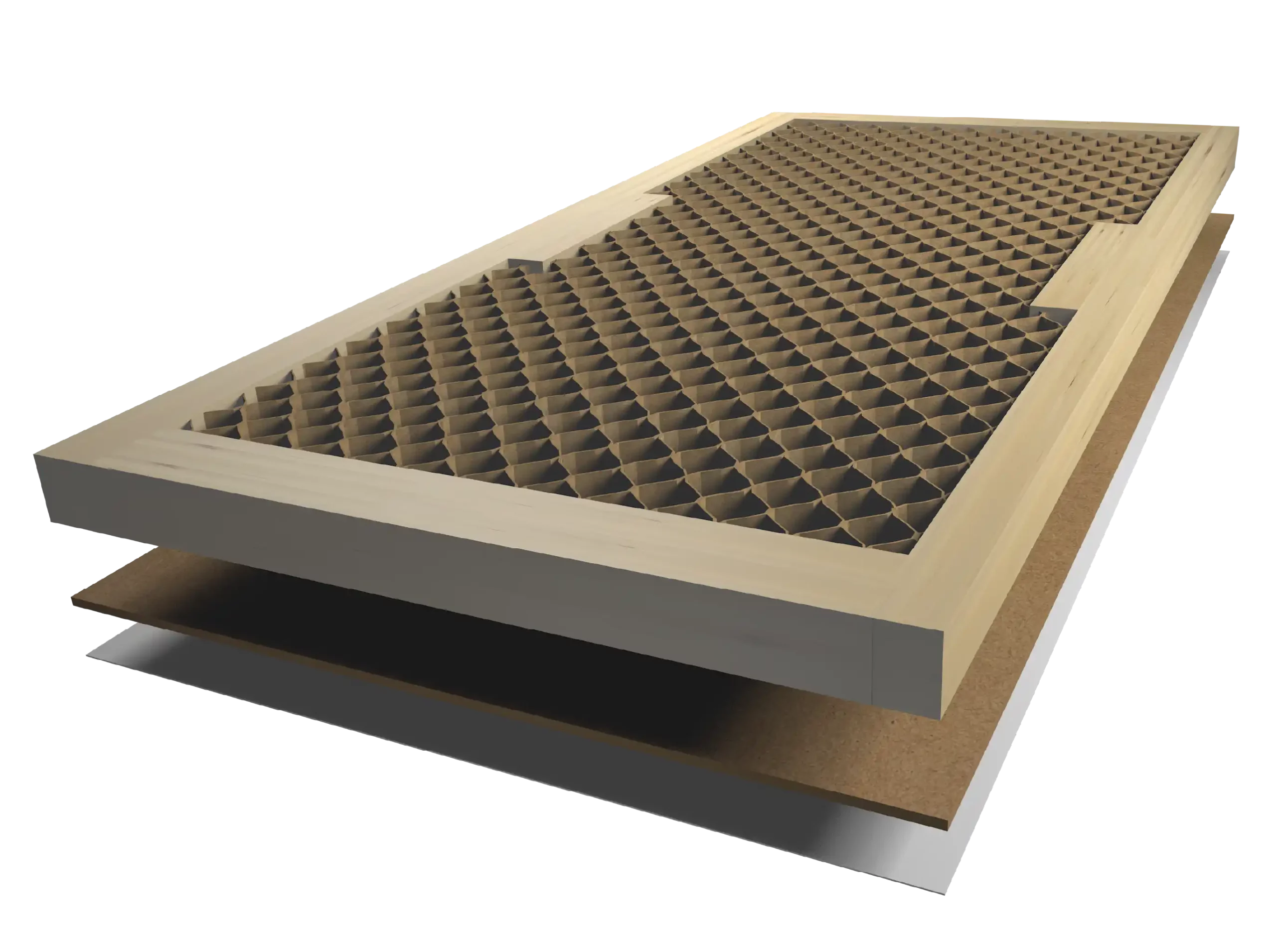

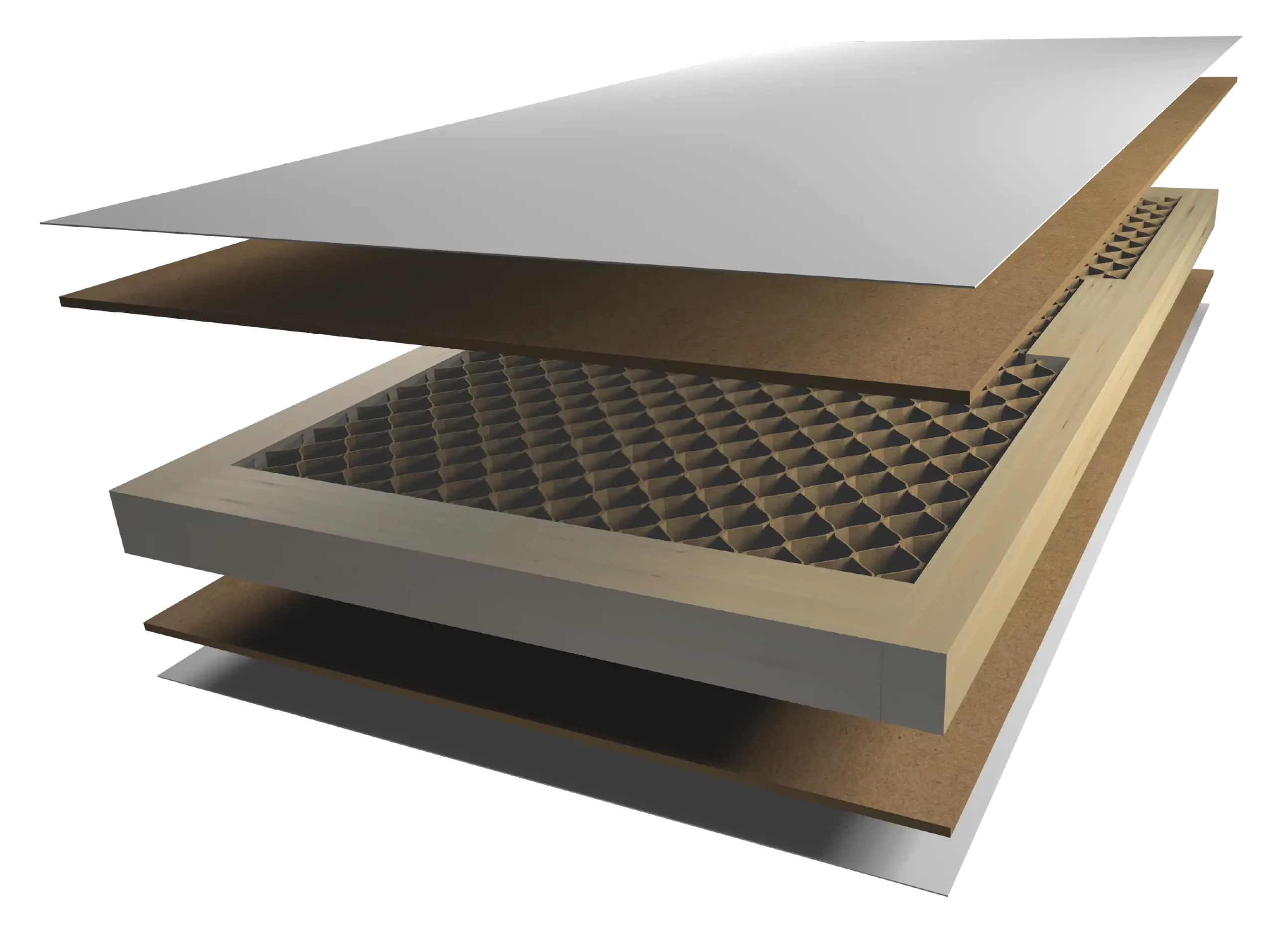

Basic structure of a lightweight sliding door blank

The VOMO lightweight sliding door blanks are divided into two product categories based on the dimensions. The ST 13 includes sliding doors up to a width of 1,300 mm, while the ST 19 variant can be manufactured in widths of up to 1,900 mm. This division has proven to be sensible based on many years of production experience. The dimensions of the cover material, waste optimisation and the optimisation of machine utilisation were the decisive factors in these analyses.

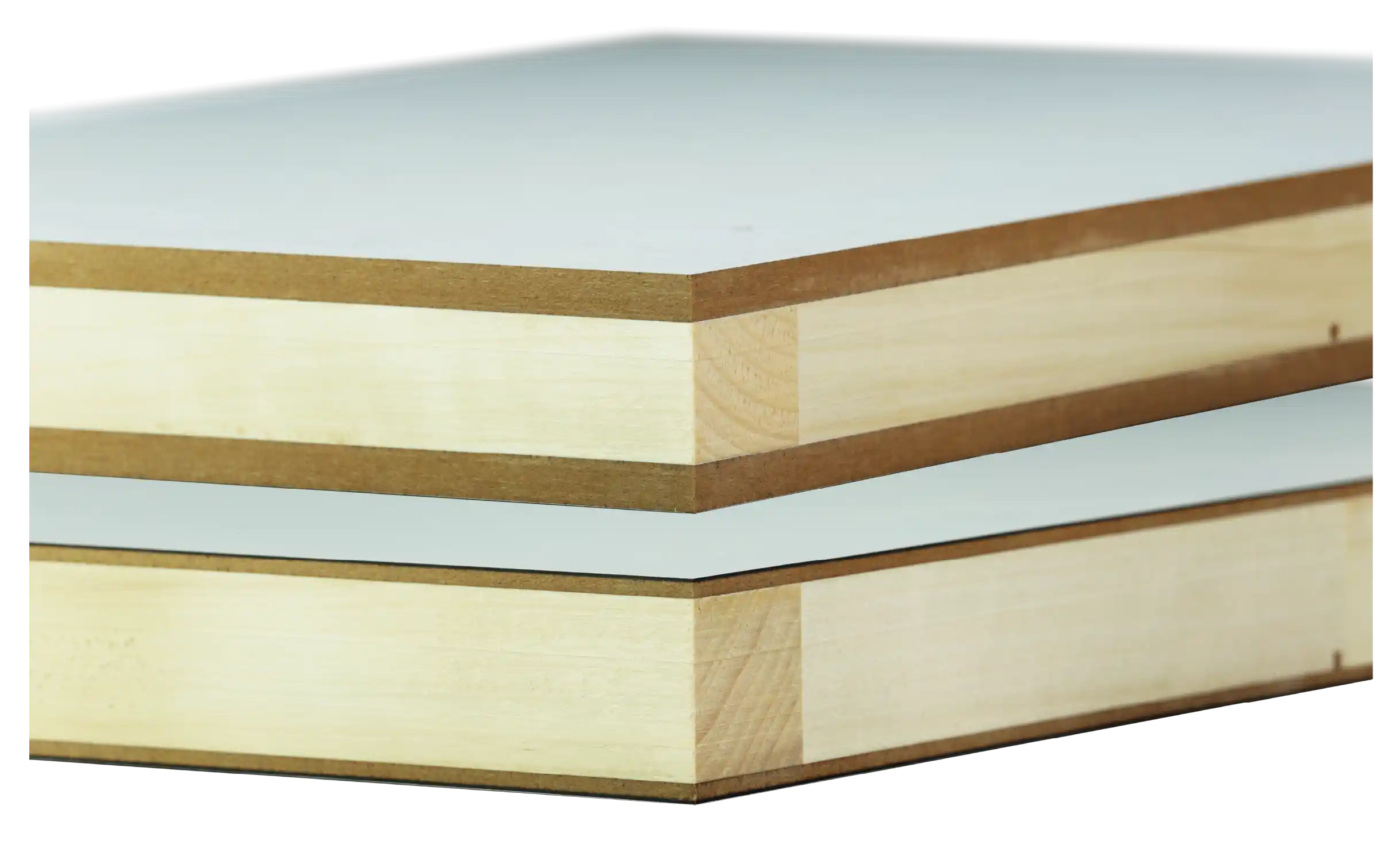

As with all VOMO products, the basic structure of the ST 13 and ST 19 sliding door blanks consists of a honeycomb core, the corresponding support decks and decorative decks as well as the board-on-frame frame material. This basic structure ensures maximum dimensional stability, especially for large formats, and is the basis for the high weight reduction compared to conventional materials.

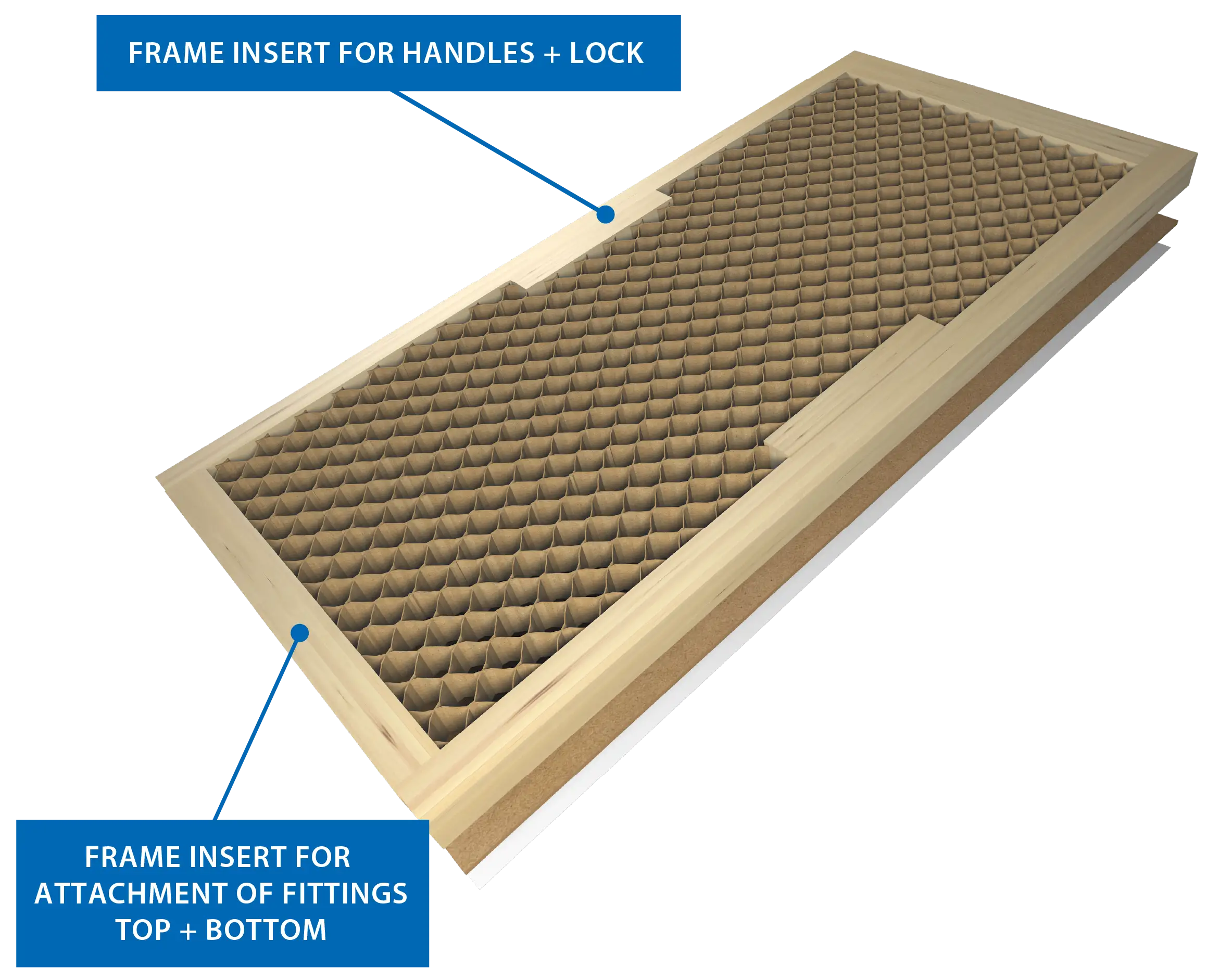

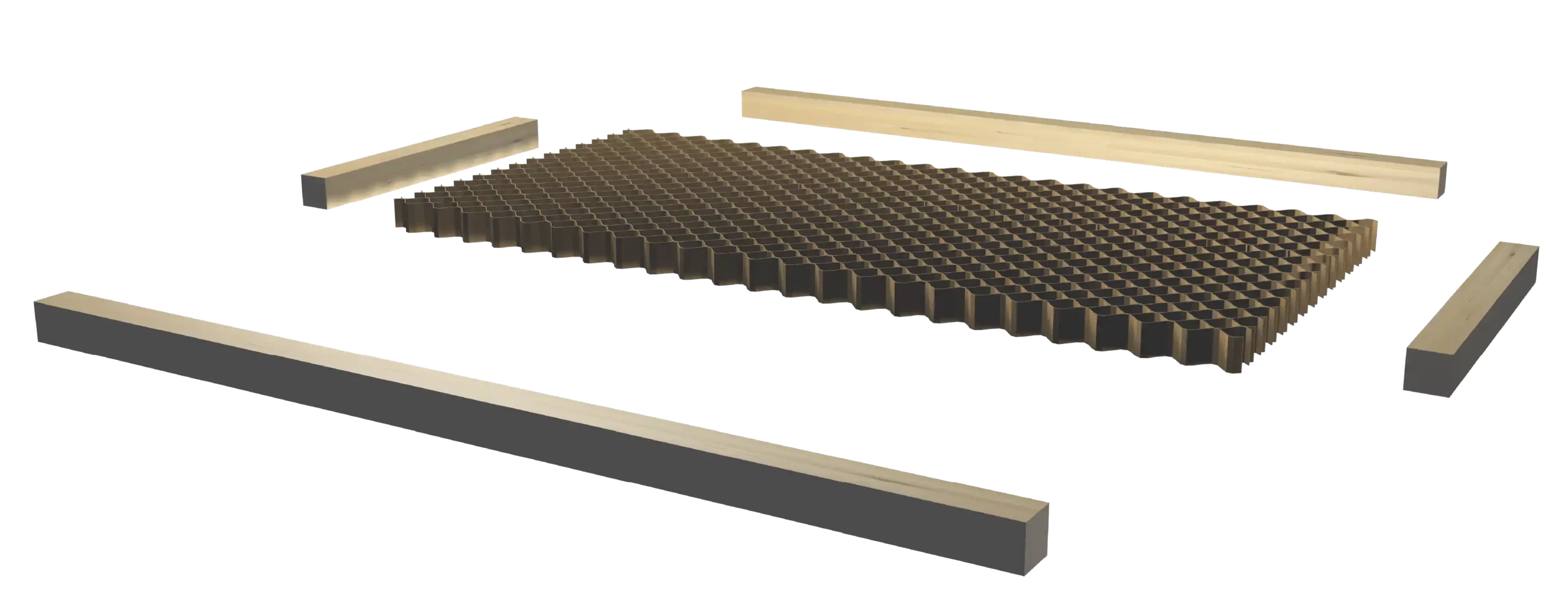

Board on frame –

the right framework

conditions

The frame material introduced during the production process is already customised to the needs of the processing customer in advance. Each standard blank in the VOMO ST series is always provided with double frames in the transverse edges as well as prepared inserts to facilitate subsequent processing by the customer for handles and locks if prior customisation is not desired.

Sliding door blanks

inserts and frames

VOMO already includes post-processing options in the basic setting of the basic blanks. Double frames on the top/bottom edges provide material for processing both the vertical and horizontal edge areas. Additional inserts for handle recess milling or lock case processing are already pressed into the element in the same way as the mirror.

Basic specifications

COVERING

Standard:

– 8 mm primer MDF

– HPL white pearl

– HPL white smooth

Variants: All decors and veneers available on the market depending on the format size

ELEMENTS

MDF: 40 mm

HPL: 39,6 mm – 8 mm

Variants: 28 – 90 mm

ELEMENT DIMENSIONS

ST 13, max. width 1300 mm

ST 19, max. width 1900 mm

Max. height 2750 mm

FRAME

Standard: Solid wood frame

Cross frame depth: doubled to 72 mm

Upright frame depth: 32 mm

Standard insert for fittings

SLIDING DOOR BLANK ARTICLE SELECTION

ST 13 | BASIC SLIDING DOOR ROD

Height: up to 2750 mm

Width: up to 1300 mm

Centre layer: honeycomb

Frame: all-round solid wood frame

Upright frame depth: approx. 32 mm

Cross frame depth: approx. 72 mm

Processing: trimmed all round incl. insert for handle and lock processing

incl. Packaging

ST 19 | BASIC SLIDING DOOR ROD

Height: up to 2750 mm

Width: up to 1900 mm

Centre layer: honeycomb Frame: all-round solid wood frame

Upright frame depth: approx. 32 mm

Cross frame depth: approx. 72 mm

Processing: trimmed all round incl. inserts for handle and lock processing

incl. packaging

PROCESSING OPTIONS

In addition to the production of basic door blanks, VOMO also offers the option of processing the products. The most common standard finishes are shown below and can easily be ordered for the selected blank. Of course, VOMO also offers the possibility of realising special processing according to customer specifications.

ABS edging

Milled handle recess

Preparation bar handle

Preparation lock case/front handle

Moulding floor groove

Milled trolley

ABS EDGE

The upright edges of the selected sliding door blank are already covered with an ABS edge (1 mm). These have the same decor as standard, but special decors or primer edges are possible at any time.

MILLINGS HANDLE CUSHEL

One-sided or double-sided handle shell millings are made inthe selected sliding door blank on the basis of the selected shell handle.

PREPARATIONS FOR BAR HANDLES

Based on the desired customer article and the specification for position and height, all necessary pre-drilling and milling is already carried out.

MILLINGS FOR

LOCK CASE / LOCK HANDLE

Here too, processing is based on customer data and is adapted to the individually selected hardware items and their specifications.

PREPARATION FOR TROLLEY

The sliding door blank is customised to match the desired trolley fitting. The processing basis here is the data of the selected fitting and its specification.

MILLED FLOOR GROOVE

Fitting-specific groove depths and widths are realised in the desired design (exposed / milled through). This makes it easy to adapt to selected hardware and guide systems.